In the world of manufacturing and machining, precision and accuracy are paramount. To ensure that parts are made to exact specifications, manufacturers rely on a variety of tools designed to hold, support, and guide materials through the production process. Two of the most important tools in this regard are jigs and fixtures. These tools help streamline production, reduce human error, and enhance overall efficiency. Although the terms “jig” and “fixture” are often used interchangeably, they serve distinct functions in the manufacturing process.

This article delves into the definition, types, uses, and importance of jigs and fixtures in modern manufacturing.

What Are Jigs and Fixtures?

Definition of Jigs

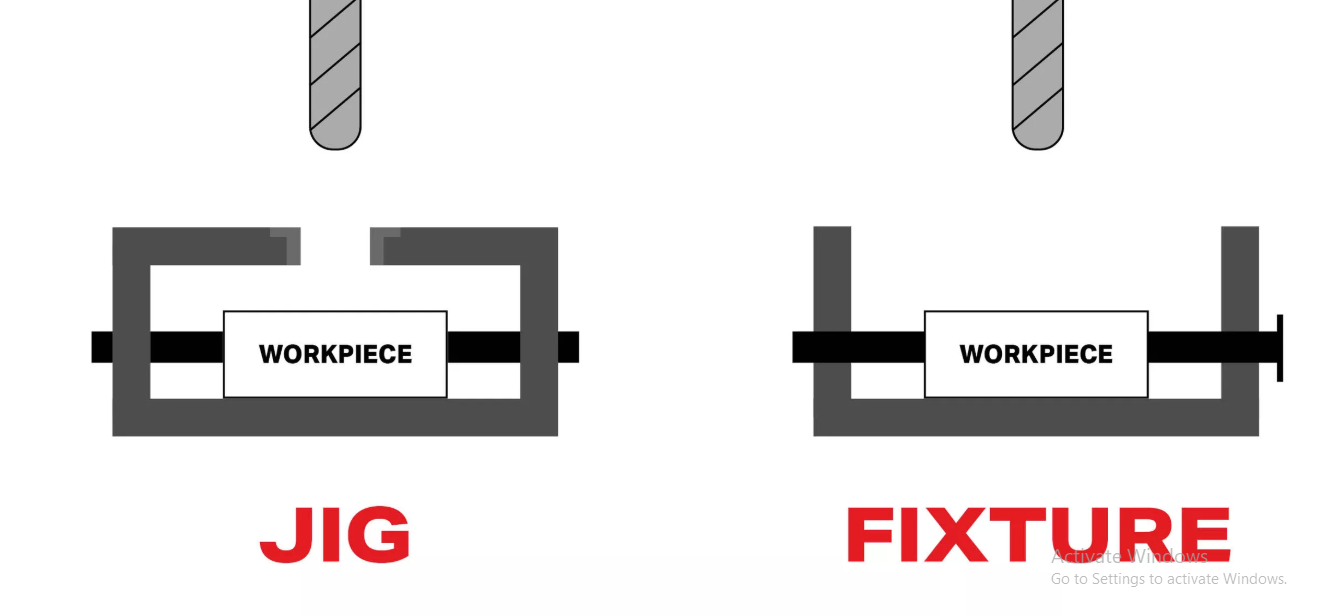

A jig is a custom-made tool used in the manufacturing process to control the location and movement of the workpiece. Jigs are designed to hold and guide tools or machine parts during operations like drilling, milling, or turning. The primary role of a jig is to ensure that the machining operation is performed at the correct location, orientation, and angle. Jigs often include features such as guides, stops, and other mechanisms that ensure precise positioning of tools.

Definition of Fixtures

A fixture, on the other hand, is a tool used to securely hold the workpiece in place during machining or assembly. Unlike a jig, a fixture does not guide the tool, but rather provides a stable platform for the workpiece to remain stationary throughout the process. Fixtures are typically used for operations like grinding, turning, or welding, where the workpiece must be held rigidly while being processed.

Key Differences Between Jigs and Fixtures

While both jigs and fixtures serve the purpose of securing workpieces, they differ significantly in terms of functionality:

- Jigs guide the cutting tool and hold the workpiece in a fixed position during operations.

- Fixtures hold the workpiece securely in place but do not guide the cutting tool. The focus is on the workpiece’s stability rather than the positioning of the tool.

The Role of Jigs and Fixtures in Manufacturing

The main function of both jigs and fixtures is to improve the efficiency and accuracy of the manufacturing process. Here are some ways in which they are essential:

Improving Precision and Accuracy

In manufacturing, even minor inaccuracies can result in defects or inconsistencies in the final product. Jigs and fixtures are specifically designed to prevent such issues by ensuring that each workpiece is positioned precisely every time. By holding the workpiece in a consistent and reliable manner, jigs and fixtures help achieve tight tolerances and high-quality standards.

Increasing Efficiency and Productivity

The use of jigs and fixtures minimizes the time and effort required for setups between operations. Workers don’t need to spend time manually positioning the workpiece, as the fixture or jig will do that automatically. Additionally, the use of jigs and fixtures allows for faster cycle times, as parts can be processed quickly and with fewer errors.

Enhancing Repeatability

One of the greatest advantages of using jigs and fixtures is the ability to replicate the same results consistently. In mass production settings, where thousands or even millions of identical parts need to be produced, jigs and fixtures are invaluable. They ensure that every workpiece is identical, with no variation in terms of measurements or finishes.

Reducing Labor Costs and Human Error

By automating the process of positioning and guiding tools, jigs and fixtures reduce the reliance on human operators to manually perform these tasks. This reduces the chance of mistakes, thus lowering the costs associated with defective parts or rework. As a result, manufacturing processes become more cost-effective and streamlined.

Types of Jigs and Fixtures

Types of Jigs

Jigs come in various forms, each designed for a specific purpose. Below are some of the most common types of jigs used in manufacturing:

- Drill Jigs: Drill jigs are one of the most common types of jigs used in manufacturing. They are used to guide drills, ensuring that holes are drilled at the correct depth, angle, and location. Drill jigs typically feature guide bushings, which provide a precise guide for the drill bit.

- Boring Jigs: Boring jigs are used to enlarge existing holes with high precision. They are often used in operations where the dimensions of a hole need to be increased slightly.

- Milling Jigs: Milling jigs are designed to hold the workpiece in place while it is being milled. These jigs are typically used in operations that involve cutting or shaping the material, such as in the case of slots, grooves, or cavities.

- Assembly Jigs: Assembly jigs are used to align and hold parts together during assembly processes. These jigs help ensure that the parts are positioned properly, reducing assembly errors and improving efficiency.

Types of Fixtures

Fixtures, like jigs, come in a variety of types depending on the manufacturing process. Some of the most common types of fixtures include:

- Vices and Clamps: Vices and clamps are commonly used fixtures in the manufacturing process. These tools are designed to hold workpieces firmly while operations such as turning, grinding, or drilling are performed. They are available in various sizes and configurations to accommodate different workpiece shapes and sizes.

- Welding Fixtures: Welding fixtures are used in the welding process to secure parts in place while they are being welded. These fixtures ensure that the components are properly aligned, minimizing the risk of misalignment and distortion during welding.

- Grinding Fixtures: Grinding fixtures are used to hold workpieces steady during grinding operations. These fixtures help ensure that the workpiece does not move, which could cause uneven grinding or damage to the part.

- Positioning Fixtures: Positioning fixtures are used to position workpieces accurately in relation to other components or parts. These fixtures are particularly useful in operations that require exact alignment, such as in the automotive or aerospace industries.

Benefits of Using Jigs and Fixtures

- Increased Production Speed: Jigs and fixtures significantly increase the speed of production. The time spent in setup and positioning is greatly reduced, allowing workers to focus on other tasks. This leads to faster production times and, in turn, a higher output of goods.

- Enhanced Safety: By securing the workpiece and tool in place, jigs and fixtures reduce the need for manual handling during operations. This reduces the risk of accidents, injuries, and defects caused by incorrect tool handling.

- Cost Efficiency: The use of jigs and fixtures helps reduce costs associated with rework, defective parts, and wasted materials. By ensuring accuracy from the start, manufacturers can avoid expensive mistakes and re-production, ultimately lowering costs.

- Quality Control: The repeatability and precision enabled by jigs and fixtures contribute to higher quality standards in manufacturing. This is especially crucial for industries that require strict adherence to safety and quality regulations, such as aerospace or automotive sectors.

Conclusion

Jigs and fixtures are essential components in modern manufacturing. These tools not only improve precision, repeatability, and efficiency but also help reduce human error and production costs. As industries continue to demand higher standards of quality and faster production times, the role of jigs and fixtures will only become more crucial in ensuring that manufacturing operations run smoothly and economically.

For manufacturers aiming to improve their production processes, investing in the proper jigs and fixtures is a smart choice that can result in long-term benefits. Whether it’s improving speed, reducing errors, or enhancing product quality, jigs and fixtures are indispensable tools for achieving manufacturing excellence.