Extrusion and injection molding are two of the most commonly used manufacturing processes in the plastics industry. Both methods play a vital role in creating products for a variety of industries, including automotive, construction, packaging, and medical devices. While they share similarities, their differences in functionality, cost, and application determine which process is best suited for specific production needs.

Extrusion is a continuous process where raw material is pushed through a shaped die to create long, uniform products such as pipes, sheets, and films. On the other hand, injection molding is a batch process that involves injecting molten material into a mold cavity, allowing for the production of complex, highly detailed components like bottle caps, automotive parts, and medical syringes. Understanding the key differences between these two methods helps businesses choose the right process for their production requirements.

Differences in Manufacturing Process

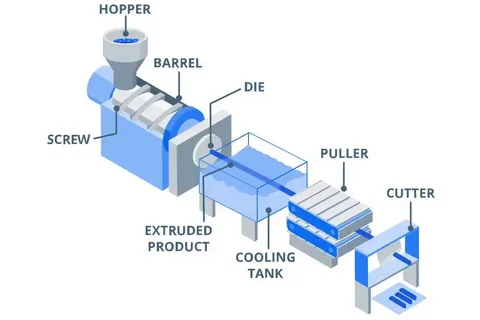

Extrusion is a straightforward manufacturing process in which plastic or metal material is melted and continuously forced through a die. The shape of the die determines the cross-sectional profile of the final product, making extrusion ideal for producing long and continuous shapes. Once extruded, the material is cooled and cut to the desired length. This process is widely used for making tubes, pipes, and profiles with consistent cross-sections.

Injection molding, in contrast, involves Extrusion vs Injection Molding plastic or other materials into a mold cavity at high pressure. The material cools and solidifies, taking the shape of the mold before being ejected. This process is best for creating high-precision, intricate components in large volumes. Since each part is individually molded, injection molding is well-suited for mass production with detailed and repeatable features.

Material Usage and Suitability

Material selection plays a crucial role in both extrusion and injection molding. Extrusion is commonly used for thermoplastics such as PVC, polyethylene, and polypropylene due to their ability to soften and harden repeatedly. It also works well for metals like aluminum and copper, which are often extruded into bars, rods, and structural components. The process is highly efficient for producing long and continuous shapes with consistent mechanical properties.

Injection molding, however, allows for greater material diversity, including thermoplastics, thermosetting polymers, and elastomers. This process accommodates materials requiring precise shaping and finishing, such as polycarbonate, ABS, and nylon. Because of its ability to mold complex geometries, injection molding is preferred for applications that demand high strength, impact resistance, and detailed aesthetic features.

Cost and Production Efficiency

Cost efficiency is a significant factor when deciding between extrusion and injection molding. Extrusion is generally more cost-effective for high-volume production of continuous products, as it minimizes material waste and maximizes throughput. The tooling costs for extrusion dies are relatively low, making it a cost-efficient option for producing large batches of uniform profiles. Additionally, the continuous nature of extrusion allows for streamlined production with minimal downtime.

Injection molding, on the other hand, has higher initial tooling costs due to the complexity of mold fabrication. However, once the mold is created, the per-unit cost decreases significantly in mass production. The process is highly automated, reducing labor costs and ensuring consistency across large batches. While the upfront investment may be higher, injection molding offers substantial cost savings for intricate and high-precision components manufactured in bulk.

Applications and Industry Use Cases

Extrusion is widely used in industries that require long, uniform products with consistent mechanical properties. The construction industry, for example, relies on extruded materials for producing window frames, pipes, and insulation components. The packaging industry also benefits from extrusion for manufacturing plastic films and sheets used in food containers and wrapping materials.

Injection molding, in contrast, serves industries requiring detailed, high-precision components. The automotive sector depends on injection-molded parts for dashboards, bumpers, and interior fittings. In the medical industry, injection molding is essential for producing syringes, surgical instruments, and device housings with strict quality and safety requirements. The ability to create complex shapes with excellent repeatability makes injection molding a preferred choice for consumer electronics, aerospace, and household goods as well.

Conclusion: Choosing the Right Process

Choosing between extrusion and injection molding depends on several factors, including product design, material properties, production volume, and cost considerations. Extrusion is the preferred choice for manufacturing long, uniform profiles with high efficiency, making it ideal for construction and packaging applications. The simplicity of the process and lower tooling costs make it a cost-effective solution for continuous production.

Injection molding, on the other hand, excels in producing intricate and precise components in large quantities. Its ability to handle complex geometries, diverse materials, and stringent quality standards makes it indispensable for industries such as automotive, medical, and consumer goods. Ultimately, businesses must evaluate their specific production needs to determine which method aligns best with their goals and budget.