In the rapidly evolving landscape of modern manufacturing, precision and customization are paramount. Injection molding, a versatile and efficient production process, plays a pivotal role in meeting these demands. From automotive parts to medical devices, custom injection molding products have revolutionized the way industries produce high-quality components with exceptional accuracy and repeatability. This article explores the essential aspects of custom injection molding, highlighting its benefits, key materials, design considerations, and its role in various industries.

Understanding Custom Injection Molding Products

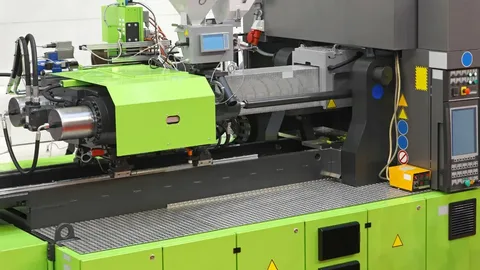

Custom injection molding is a manufacturing technique that involves injecting molten material into a custom-designed mold to produce complex and precise parts. Unlike standard molds, custom molds are tailored to the unique specifications of each client, enabling manufacturers to create highly specialized injection molding products. These products can range from intricate medical components to durable automotive parts, all created with exceptional precision and consistency.

The customization in injection molding allows for various shapes, sizes, and complexities that might be impossible or costly with other manufacturing methods. The process enables manufacturers to meet specific industry standards and design requirements, making it a crucial component in sectors that demand exacting standards, such as aerospace, healthcare, and electronics. By utilizing custom injection molding, companies can produce products that are not only high-quality but also highly specialized.

Key Materials Used in Injection Molding Products

Choosing the right material is fundamental to the success of custom injection molding. Different materials offer various properties, which can impact the durability, flexibility, and performance of the final product. Some of the most common materials used include thermoplastics like polypropylene, polyethylene, and ABS, as well as engineering-grade resins such as nylon and polycarbonate. These materials are favored for their strength, flexibility, and ability to withstand environmental stress.

In recent years, there has been a growing demand for sustainable and recyclable materials in injection molding. Materials like bioplastics and recycled resins are being increasingly used in custom injection molding products, providing eco-friendly alternatives for industries seeking to reduce their environmental footprint. By selecting appropriate materials, manufacturers can create products that meet both functional and environmental requirements, ultimately enhancing the appeal and usability of injection molding products.

Design Considerations for Precision in Custom Injection Molding

Precision is a defining characteristic of custom injection molding products. Designing a mold requires careful consideration of factors such as part geometry, tolerance levels, and the material’s properties. A well-designed mold not only ensures accuracy but also minimizes defects and waste, making the production process more efficient. During the design phase, engineers use computer-aided design (CAD) software to create precise models that guide the mold-making process, allowing for extremely detailed and accurate parts.

Another crucial aspect of mold design is the consideration of factors such as cooling time and shrinkage. Proper cooling helps prevent warping and other defects, while accounting for material shrinkage ensures that the finished product maintains its intended shape and size. By carefully planning the design, manufacturers can produce injection molding products that meet the highest standards of precision, which is essential for industries like medical devices and aerospace, where even the smallest deviation can lead to significant consequences.

Applications of Custom Injection Molding in Various Industries

Custom injection molding products have applications in a wide array of industries, each with unique demands and specifications. In the automotive industry, injection molding is essential for producing parts such as dashboards, bumpers, and engine components. The precision and consistency offered by custom injection molding ensure that each part fits seamlessly, enhancing vehicle performance and safety. Similarly, the medical industry relies on custom injection molding for devices like syringes, surgical instruments, and implantable components, where accuracy and material purity are critical.

In the electronics industry, injection molding products are used for components such as enclosures, connectors, and switches. The customization options available allow manufacturers to meet the stringent design requirements of complex electronic devices. Beyond these sectors, custom injection molding plays a significant role in consumer goods, aerospace, and even the food and beverage industry, where specialized, high-quality components are needed for various applications. These industries benefit from the adaptability and precision of injection molding, enabling them to produce parts that are both functional and durable.

The Advantages of Custom Injection Molding for Precision Manufacturing

The advantages of custom injection molding products are extensive, particularly in industries where precision and quality are essential. One of the key benefits is the ability to produce parts with a high degree of accuracy and consistency, ensuring that each product meets exact specifications. This level of precision is essential in sectors such as healthcare and aerospace, where product reliability can have a direct impact on safety. Additionally, the automation of the injection molding process allows for high-volume production with minimal human error, reducing the cost per part and enhancing overall efficiency.

Another major advantage of custom injection molding is the flexibility it offers in terms of material and design options. Manufacturers can create complex shapes, incorporate different materials, and produce multi-part assemblies all within a single process. This versatility not only broadens the scope of possible applications but also allows companies to innovate and improve product performance continuously. By leveraging the capabilities of custom injection molding, manufacturers can meet the diverse needs of modern industries while achieving the highest standards of quality and precision.

Conclusion

Custom injection molding products have transformed precision manufacturing, providing industries with the ability to create specialized, high-quality components that meet exacting standards. By focusing on the key aspects of material selection, design precision, and adaptability, injection molding continues to drive innovation across sectors. With the growing demand for sustainable and efficient manufacturing solutions, custom injection molding is poised to play an increasingly important role in shaping the future of production and enabling businesses to meet the complex demands of the modern marketplace.